At Mr. Chain, we take pride in being a top manufacturer of high-quality crowd control solutions, driven by our commitment to innovation. This dedication fuels our extensive range of meticulously designed products, tailored to meet a wide spectrum of safety and barrier requirements.

Our Core Offerings:

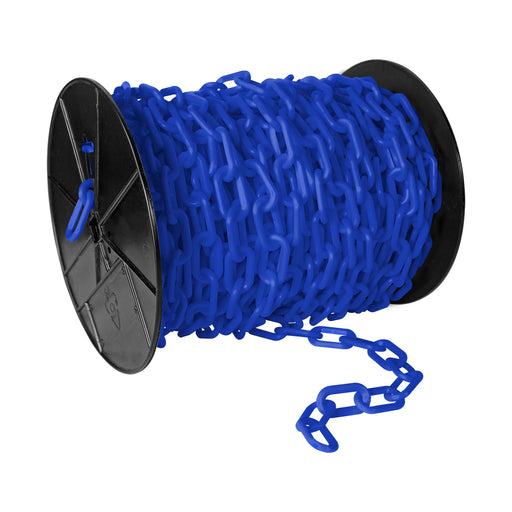

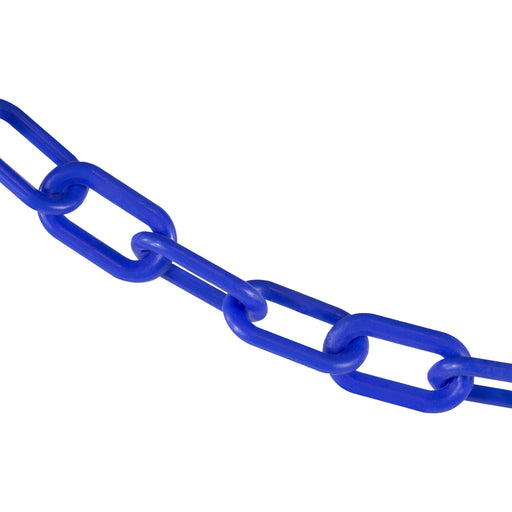

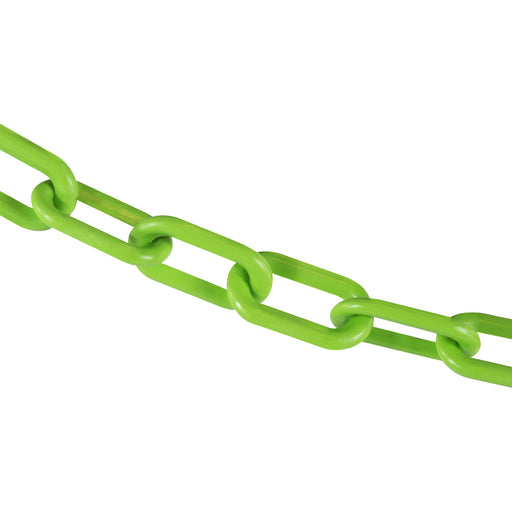

• Plastic Chain: Discover the durability and aesthetic appeal of our plastic barrier chain, suitable for both indoor and outdoor environments.

• Plastic Stanchions: Our robust and lightweight stanchions are ideal for efficiently guiding foot traffic or creating designated areas.

• Additional Safety Products: From ground poles to traffic cones and delineators, Mr. Chain has your safety needs comprehensively covered.

• Barrier Accessories: We also offer a comprehensive selection of accessories that seamlessly complement our chain, stanchions, and other products.

Why Choose Mr. Chain?

- Quality Assurance: Every product in our catalog undergoes rigorous quality checks to guarantee exceptional durability and functionality.

- USA-Made Excellence: Our products, proudly crafted in the United States, are renowned for their outstanding quality and craftsmanship.

- Flexible Shipping: Enjoy the convenience of free shipping for online orders exceeding $100 within the contiguous 48 states.

- Customer-Centric Approach: Our efficient customer service team is committed to providing clarity on orders, returns, and more, ensuring your satisfaction.